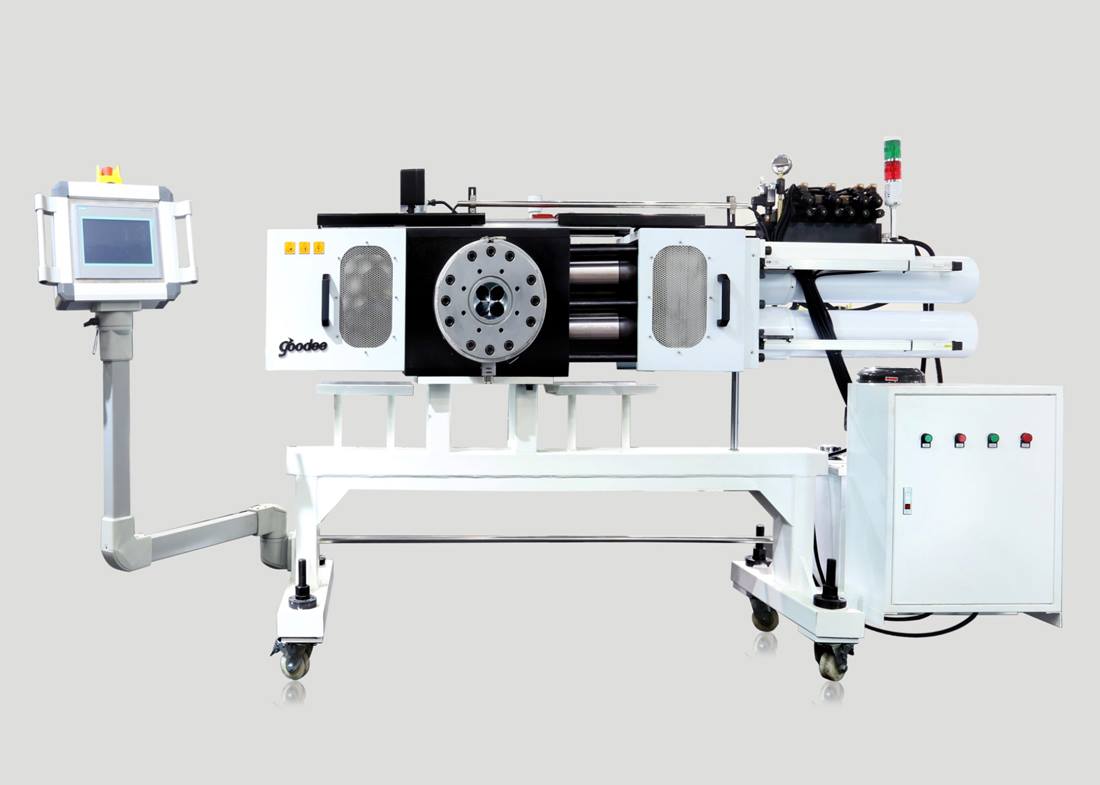

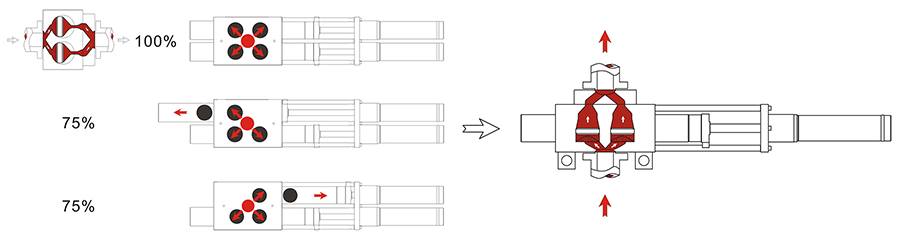

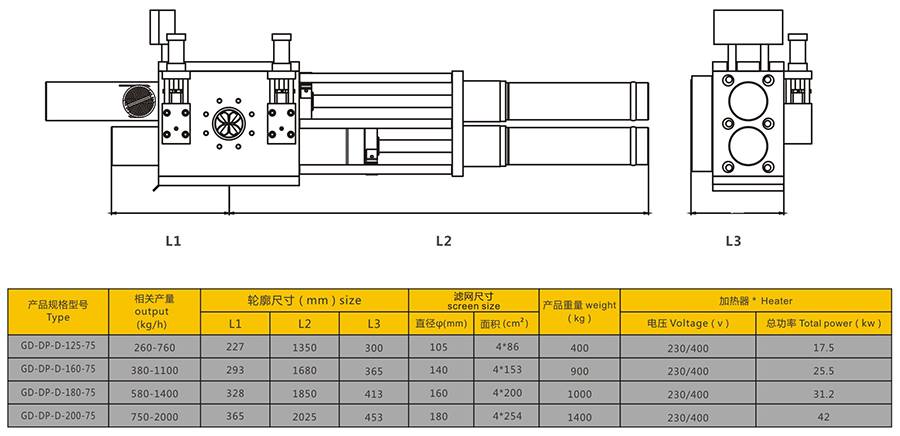

Goodee screen changer,with perfect filtering precision,is specially developed for high level automatic extrusion line.It will cause no interruption to the whole line during screen change.For the screen changer with backflush function,during its both processes of backflush and screen change,there is 75% of filtering area remained for filtering.With its high pressure-resistance,there is no pressure fluctuation during the process of screen change.

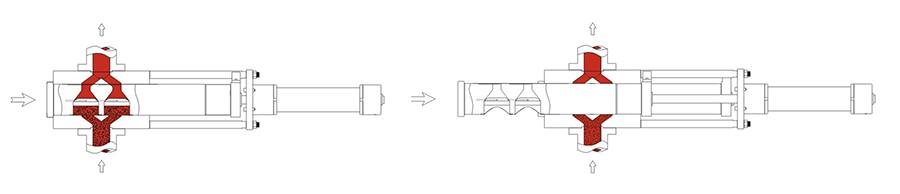

The bearing piston with changeable filter element is hydraulically moved out of the housing to allow the screen pack of the piston to be removed and replaced with a new one.After these, this piston will be reset to the working position.During the screen change,the other piston remains in the normal working position to ensure the continuous filtration.

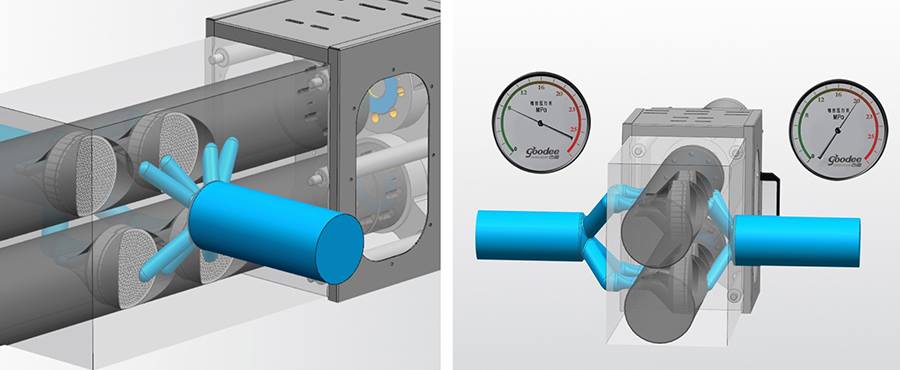

The two bearing pistons both have two screen cavities. When melt going

through the screen,the impuries will be intercepted and thus get

high-quality product.The screen is designed with high-precision, high

wear resistance and pressure resistance.

· With larger filtering area,suitable for dealing with a wide variety of polymers

· Perfect sealing effect

· Optional venting procedure,realizing the dual functions of screen changing and gas exhausting

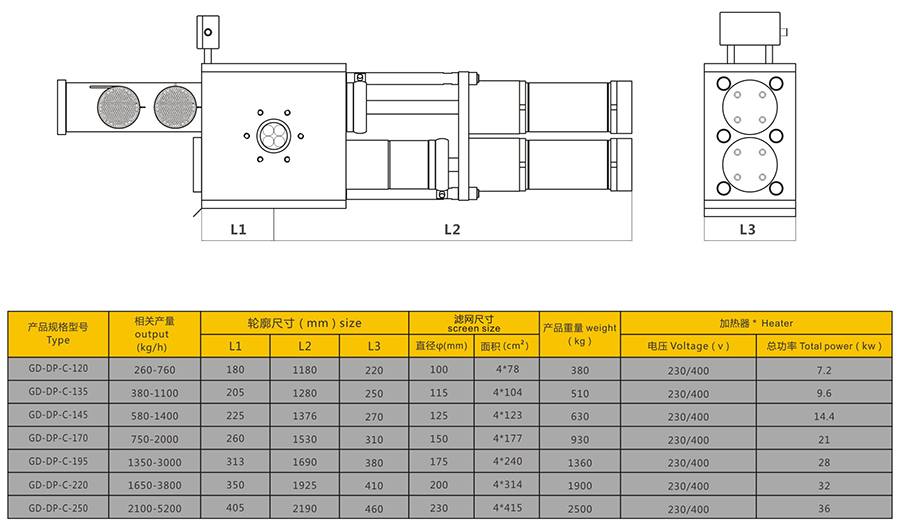

· Standard screen dimentions ranges from 80 to 250mm.Or can be customized for special size

· Operating pressure below 25Mpa,temperature below 300℃

Especially suitable for melt filtration of high-level automation production line,such as board,sheet,film,tube,fiber,cable and so on. Applicable polymer:PP,PE,ABS,PS,PET,PVB,PBT,TPE,PMMA,PC,PA,etc.

Other Products

Other Products