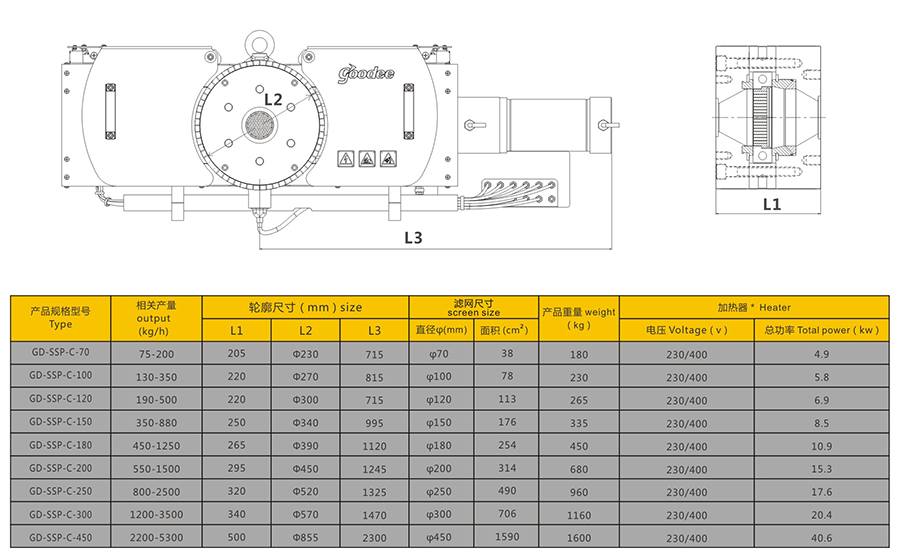

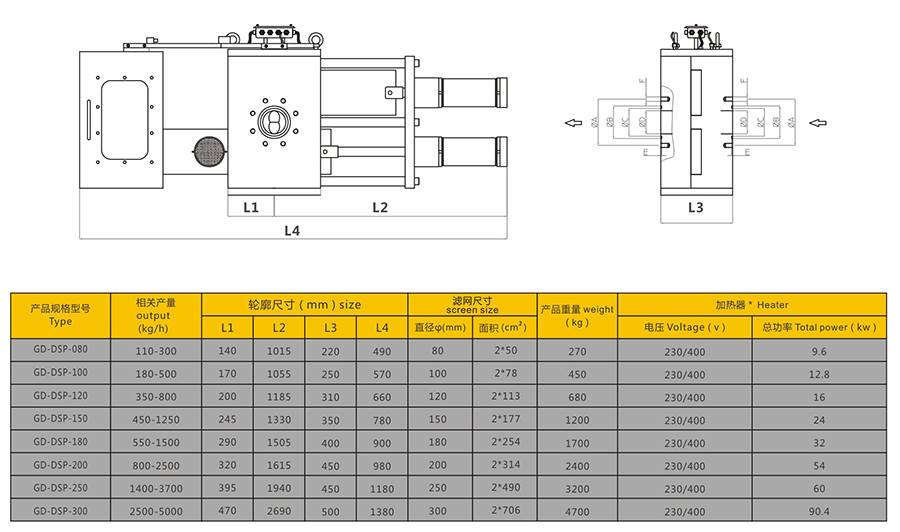

· For operating pressure,below 25Mpa and for temperature,below 300℃.

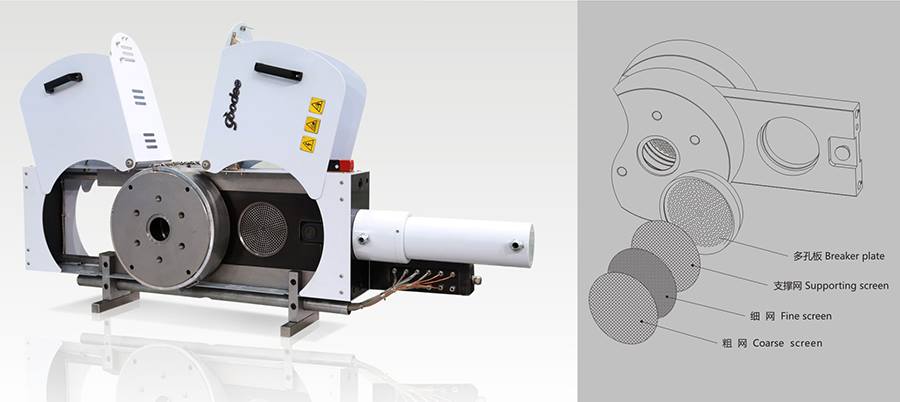

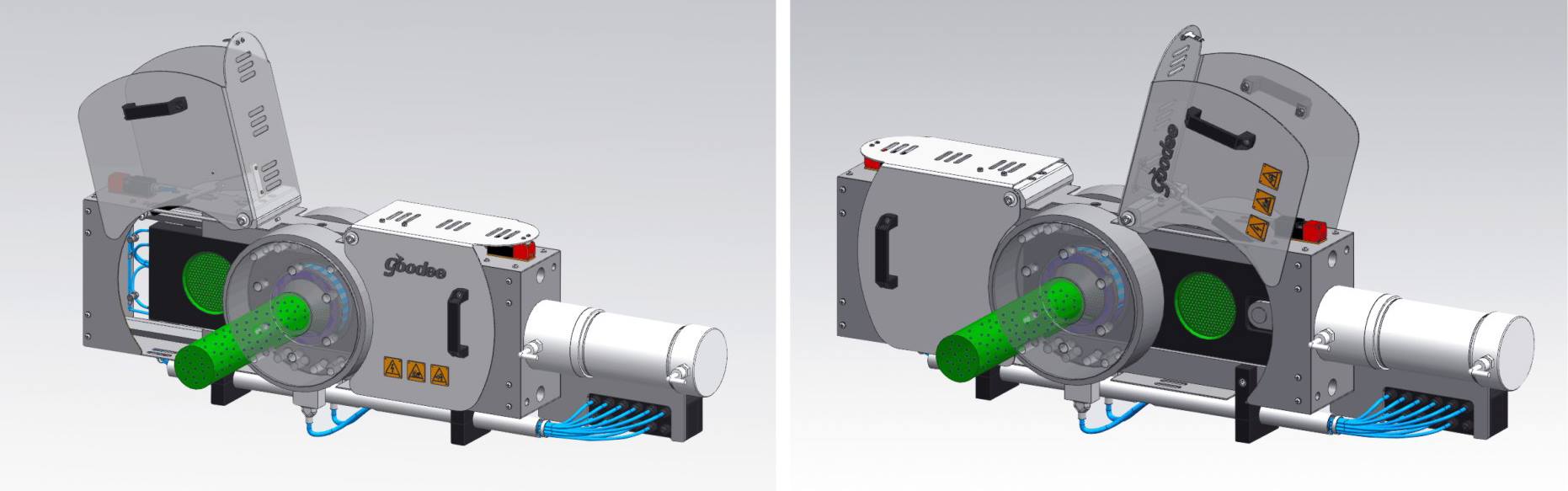

· During the screen change, the screen cavity is removed hydraulically,indexing the other one into operation.When the plate stop shifting,the protection shield will be opened.Using the related tool to quickly remove the unmelted particles and impurities, take out the used screen and put a new one.

Without halting the production during screen change.

· There are seveal models to select,or customozied.

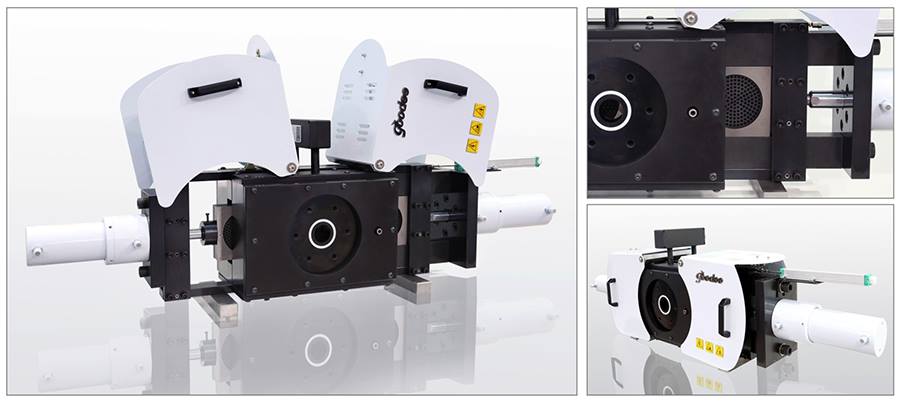

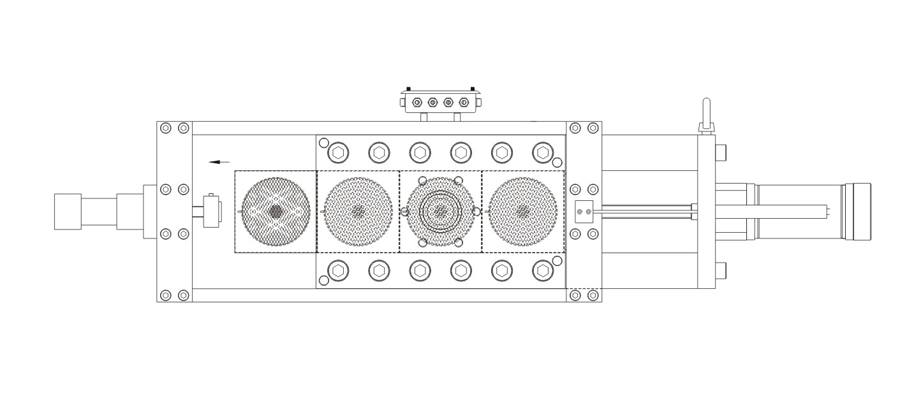

There are four square-shaped filter screen supporting plates.The hydraulic station will supply power to push each plate into working station in order. The feature of this type of screen changer is the compact interface with extruder.

Other Products

Other Products