Multi-layer co-extrusion die with high-end manufacture

The multi-layer technology is mainly divided into two methods: one is feed

With the development of science and

technology, new materials emerging, the application field of plastic

products has been amplified. The single material characteristics of

products have been unable to meet the needs of production, but

multi-layer co-extrusion technology can achieve different functions . It

can manufacture by several different materials with excellent

characteristics, the product has gradually become the new darling, for

example TPU, TPE-TPO packaging material CPP film, optical film and used

in electronic products such as PC-PMMA, the comprehensive performance of

multi-layer composite materials are widely applied in many fields.

Multilayer co-extrusion technology is mainly divided into two forms, one

is the feed block co-extrusion, and the other is the CO extrusion.

Compared with the feed block co-extrusion, the multi layer coextrusion,

has the advantages of high accuracy of the composite uniformity, the

surface layer is particularly thin or the production of the two raw

materials with different processing temperature is particularly

advantageous.

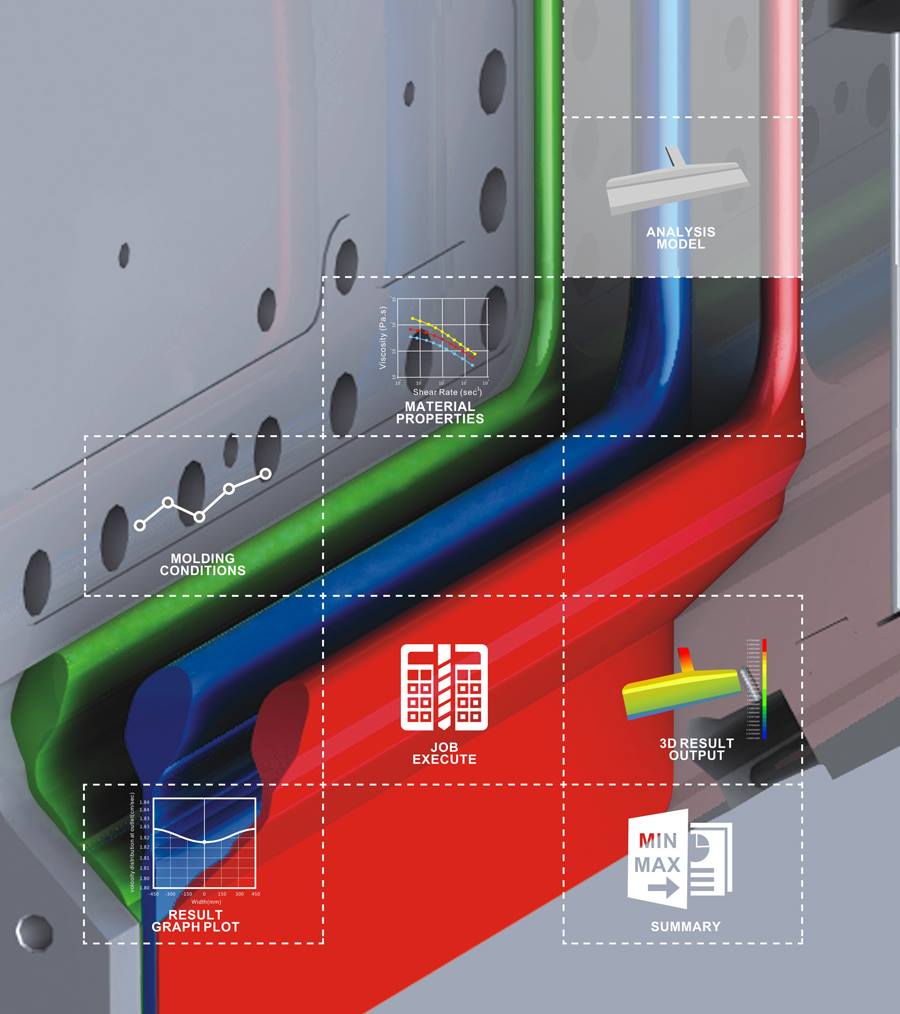

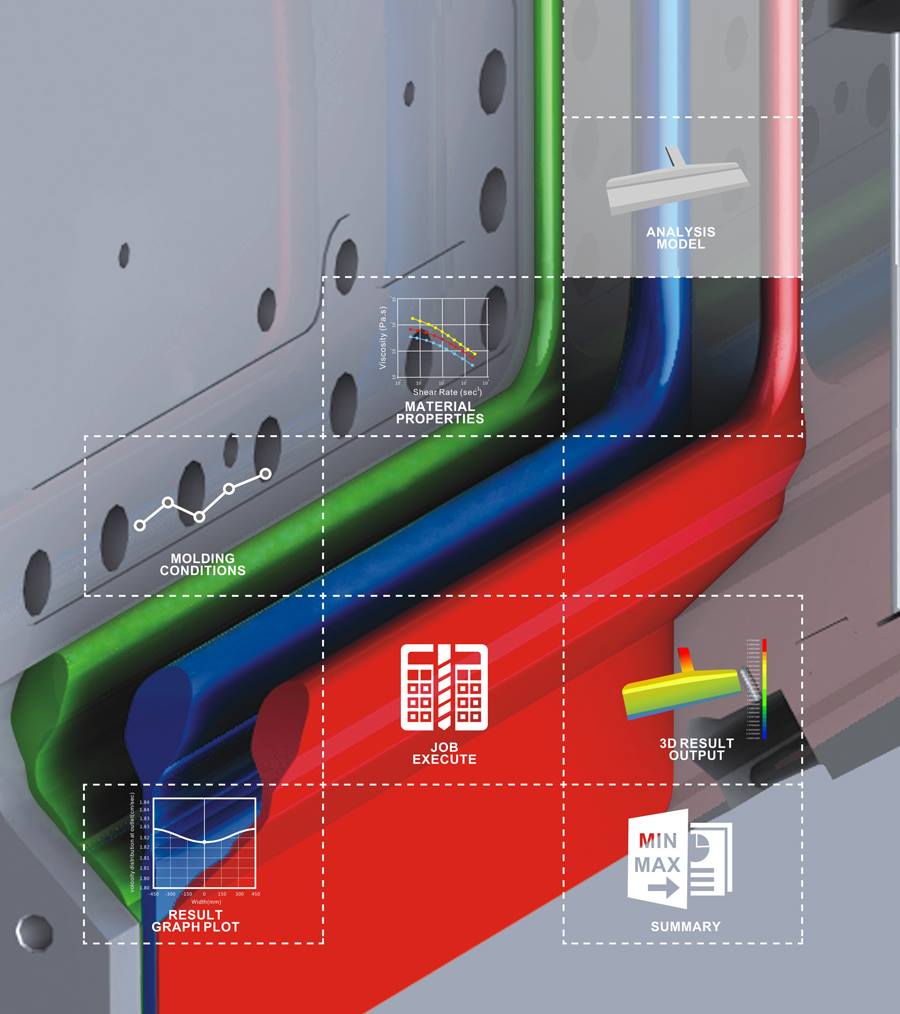

Innovation design, promote the product value

Because of the complex structure of the mold, the design and

production have a lot of difficulties. The processing precision is also

more demanding. We fully follow the physical characteristics of raw

materials, constantly trying to design, made a new breakthrough. For the

production of composite materials with large temperature difference,

using special technology and development, so that the raw material

between the feed inlet through the insulation hole, to reduce the

temperature transfer between different materials, effectively eliminate

the effect of the temperature difference between the materials.

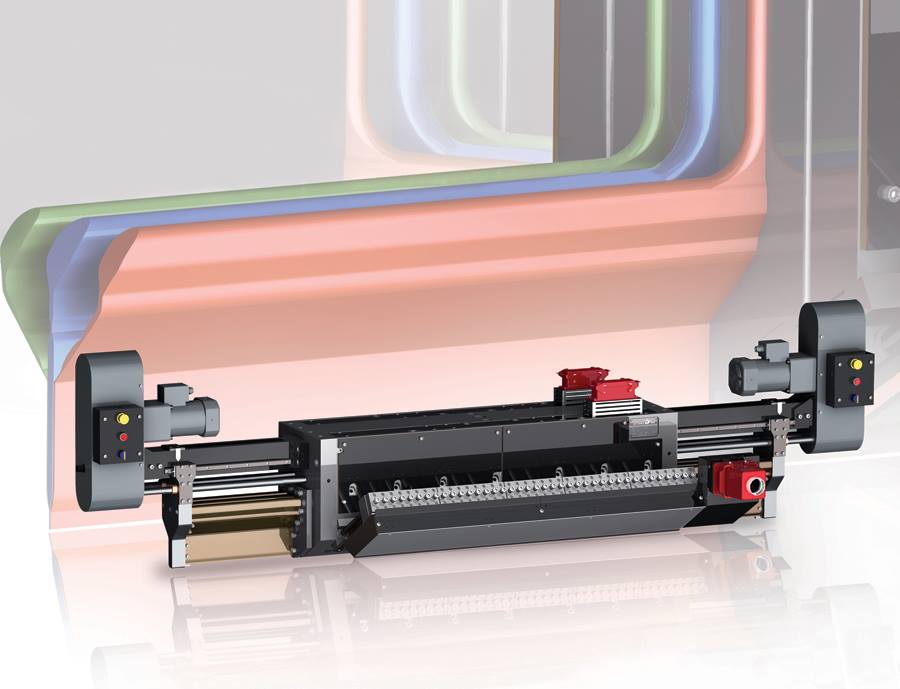

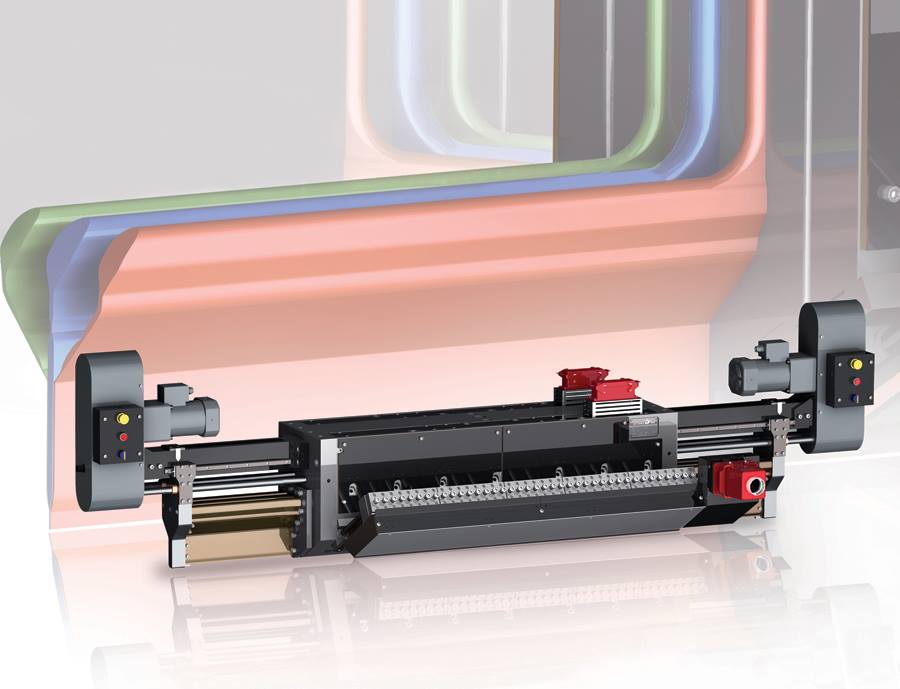

The improved mold multilayer co extrusion die with precise adjustment,

increasing the within block independent for convenient production, a

set of die head can produce a variety of different width of the

products, each composite layer can also set different block lengths,

different cutting edges, can maximum eliminate the phenomenon of

webbing, both to save the waste of raw materials, according to the

special requirements of customers for products, especially for the

frequent adjustment of different materials and different width of the

material production, designers of the PLC control system to achieve

accurate electric block wide adjustment, to avoid losses caused by the

shutdown regulation, with automatic control system using die lip the

opening gap, through the die head bolts for automatic tuning, fast and

effective control of the accuracy of products, make the composite

processing more flexible, save time Lifting efficiency.

The technical advantage of the internal multiple die compound die in the electric inner gear:

Independent internal structure, electric adjustment, suitable for different width of each layer of product production

Independent temperature control system, the realization of multi

material mold temperature difference thermal composite, the maximum

temperature difference between layers 80

Suitable for each layer of the material characteristics of the material

is more complex, the composite proportion of the error reduced to less

than 5%

PLC control system, the width of the inside, to achieve accurate and convenient production

And can be used for PP, PA, EVOH, EVA, PVDF, PVDC, PET and other temperature sensitive polymer.