Thin film coating is a kind of important modern surface engineering

technology. With the rapid development of high technology, such as nano

material and coating technology, the quality of functional film becomes

better and better. From the present point of view, there are three

purposes of the film surface coating, first is to give the film a new

function; the second is to protect the film to enhance the durability;

the third is to play a decorative role in the film. All in all, the

quality of the film can be improved by applying the functional coating

on the surface of the film.

Nowadays, the growing global oil depletion of attention and awareness of

environmental protection, energy demand will be expanded continuously

in the future, especially the increase of the touch panel ITO film

demand, the rapid growth of optical coating materials. More and more

mobile terminals are equipped with touch panel, such as smart phones,

tablet PCs.

ITO film demand is expected to continue to grow rapidly in the

future. Two battery separator lithium-ion batteries in addition to the

use of consumer electronics, the future of lithium-ion batteries for

electric vehicles will continue to increase substantially further . In

addition, more than electronic paper electronic equipment significantly

increased; organic thin-film solar cells and organic electric light have

been carried out research and development. As the next generation of

equipment substrate, is expected to further growth in the future. ITO

film demand is expected to continue to grow rapidly in the future. Two

battery separator lithium-ion batteries use for consumer electronics,

the future of lithium-ion batteries for electric vehicles will continue

to increase substantially further . In addition, more than electronic

paper electronic equipment significantly increased; organic thin-film

solar cells and organic electric light have been carried out research

and development. As the next generation of equipment substrate, is

expected to further growth in the future.

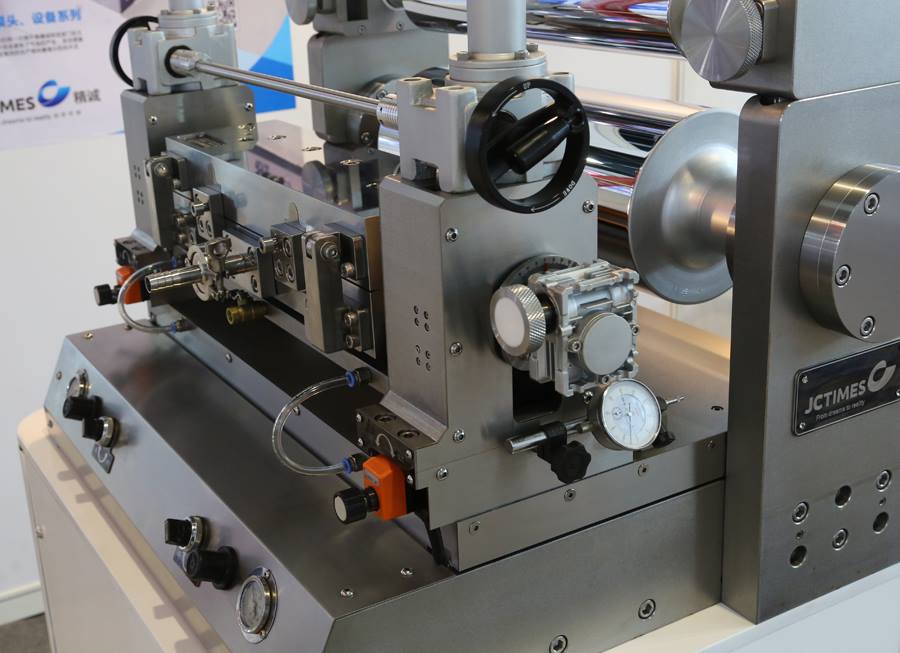

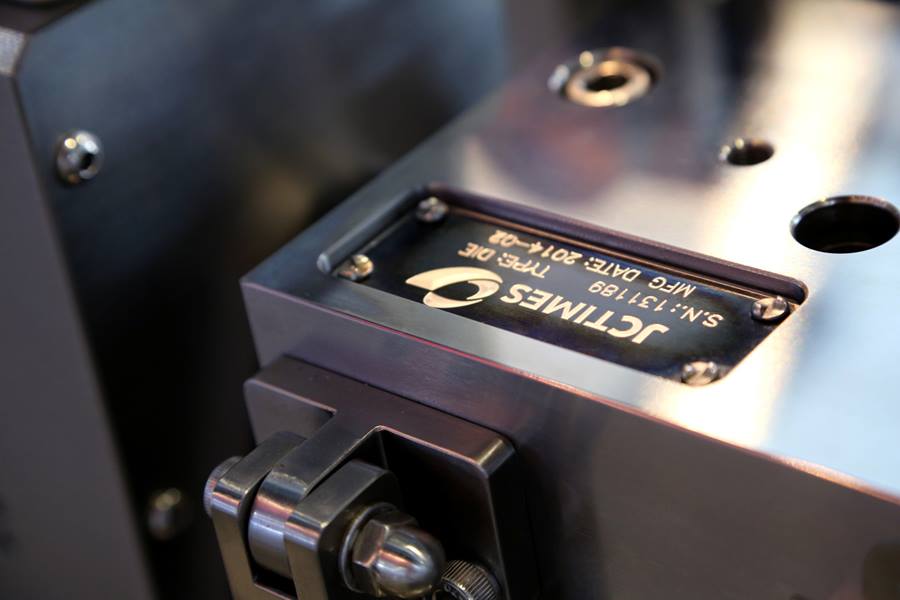

Success programme of coating die design

Film cast is coating a layer of special Material to base material.So the

thickness and precision of standard to coat layer are very high. On the

realistic process, uniform or bad coating will affect the function film

use value.Our company latest research and development of coating die

system , is an innovation of R & D department in technology, new

design completely avoids the formation of air bubbles, flexible and

convenient mode of operation, to provide the most powerful technical

support for customers in a stable and efficient production.

compared with the traditional roller coating technology,it can improve

the speed and accuracy of coating line, at the same time decreased the

impact on the environment.

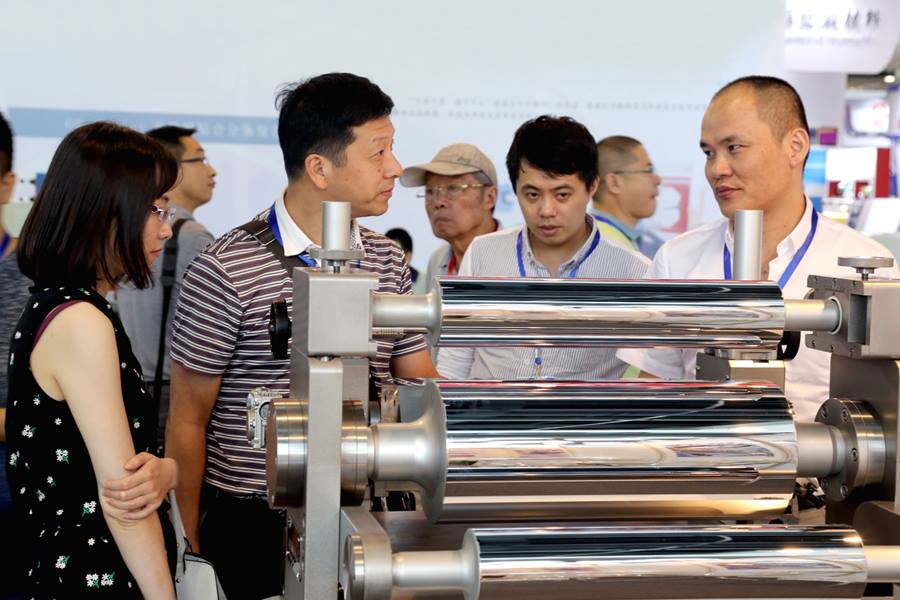

Our group coating system design, suitable for various types of hot melt adhesive, including: PSA, APAO, EVA, PA, PI, PUA and all kinds of elastomers, can produce all kinds of coat coating amount and optical transparent coating, and can make the coating amount remained at a very precise tolerance range. In addition, the creative design team is also a creative design of the airflow stability system, online cleaning function and exhaust and raw material recycling system. These designs, both from the human nature of the equipment, as well as the actual production process to solve the problem.

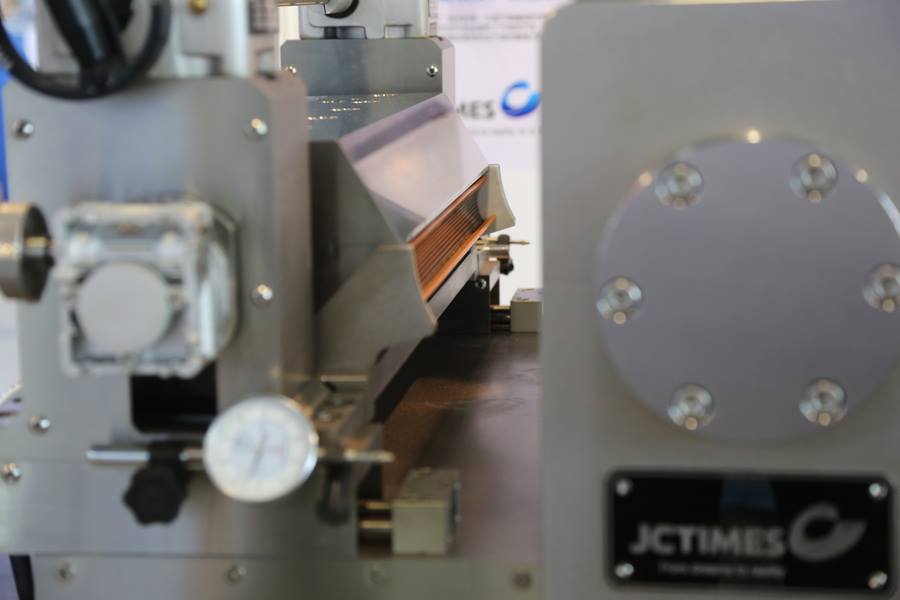

Due to the operation of substrate, plant production equipment and other high-speed traction device around, switch can lead to turbulence, causing bubbles, uneven phenomenon of coating surface, seriously affect the quality of products, the serious attitude in the experiment designed vacuum stable system, and a good solution the problem: the formation of a vacuum region between independent die and the substrate, through the air conditioning system of negative pressure, the air pressure in the region within the set range is always stable, so as to realize high speed, stable and high quality production. and complete online cleaning function of hinged design, only need to remove the locking screws, can open online die head, cleaning mold, all actions are completed on the rack, improve production efficiency, and good save material waste.