More than 35,000 extrusion dies have been sold to 8,000 end users directly or indirectly from more than 30 countries and areas.

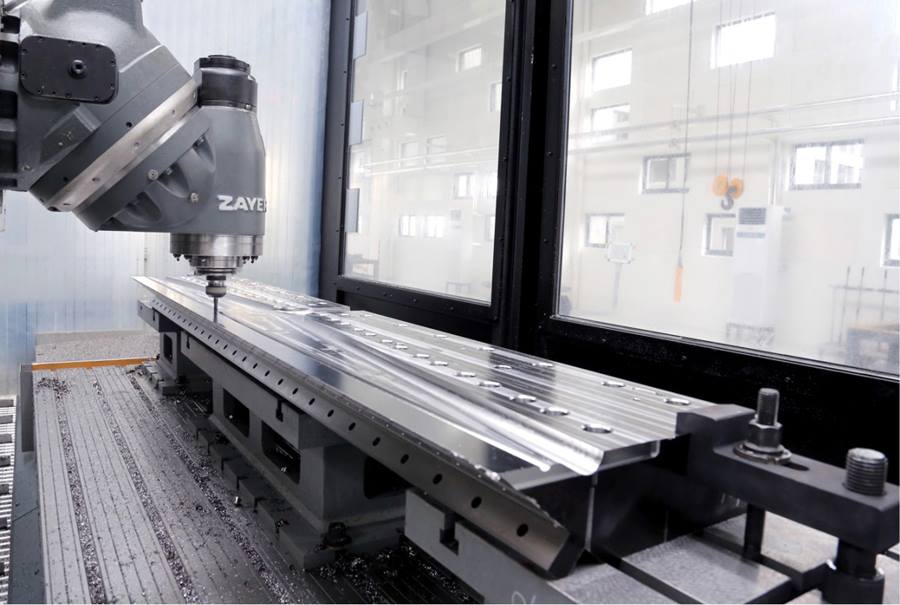

· Advanced European integrated machining center can meet the processing

of any inclined and curved surface,one-time forming with spindle 360°

rotating.Length error of 5000mm extrusion die is fixed within ±3μm.

· Alloy steel for die production: P20,2714,2311,SUS420/630,5CrNiMo,etc.

· Die surface treatment can be proceeded with nickel alloy,tungsten carbide,hard chrome and nano diamond alloy.

For chrome- plated thickness,it is from 0.02 to 0.05mm,hardness is HV900-1000.

· For special requirement for high-quality die lip,it can be processed with tungsten carbide with lip closed angle at R0.03mm.

· Engineers with more than 10 years of woking experience strictly focus on each production detail.

·

International highly-ranked instruments such as Vickers hardness

tester,chrome-plated thickness gauge,optical non-contact detector

provide accurate testing data.

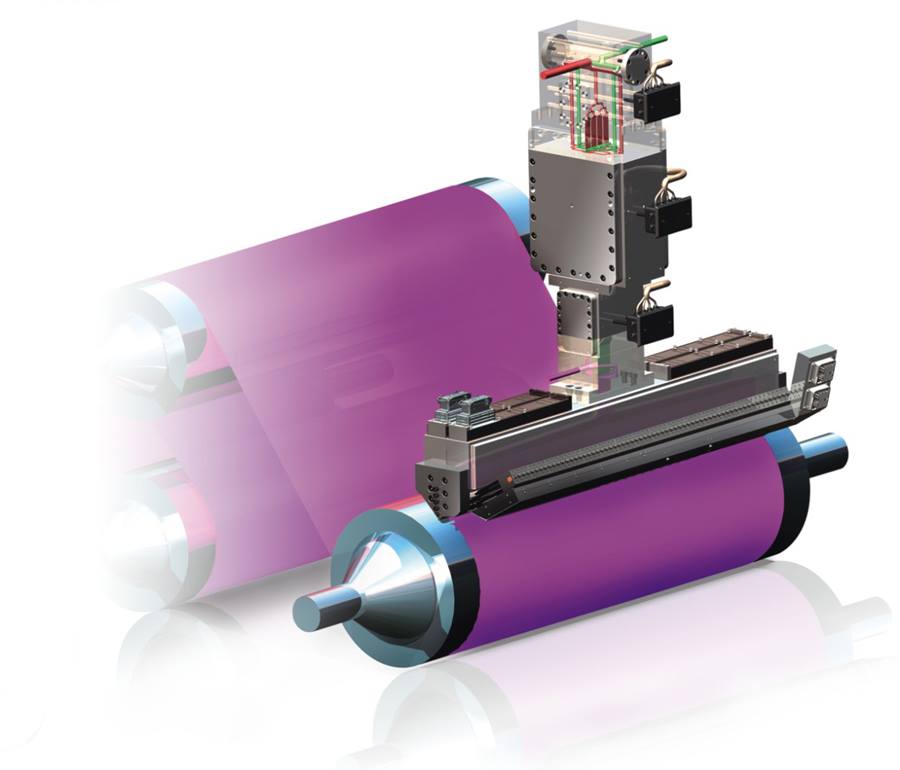

· KUNZ straightness detector is used to verify staightness tolerance of die lip with high precision and efficiency.

For 1000mm standard extrusion die,tolerance is within ±0.02mm;

For 1000mm precise coating die,tolerance is within ±0.002mm.

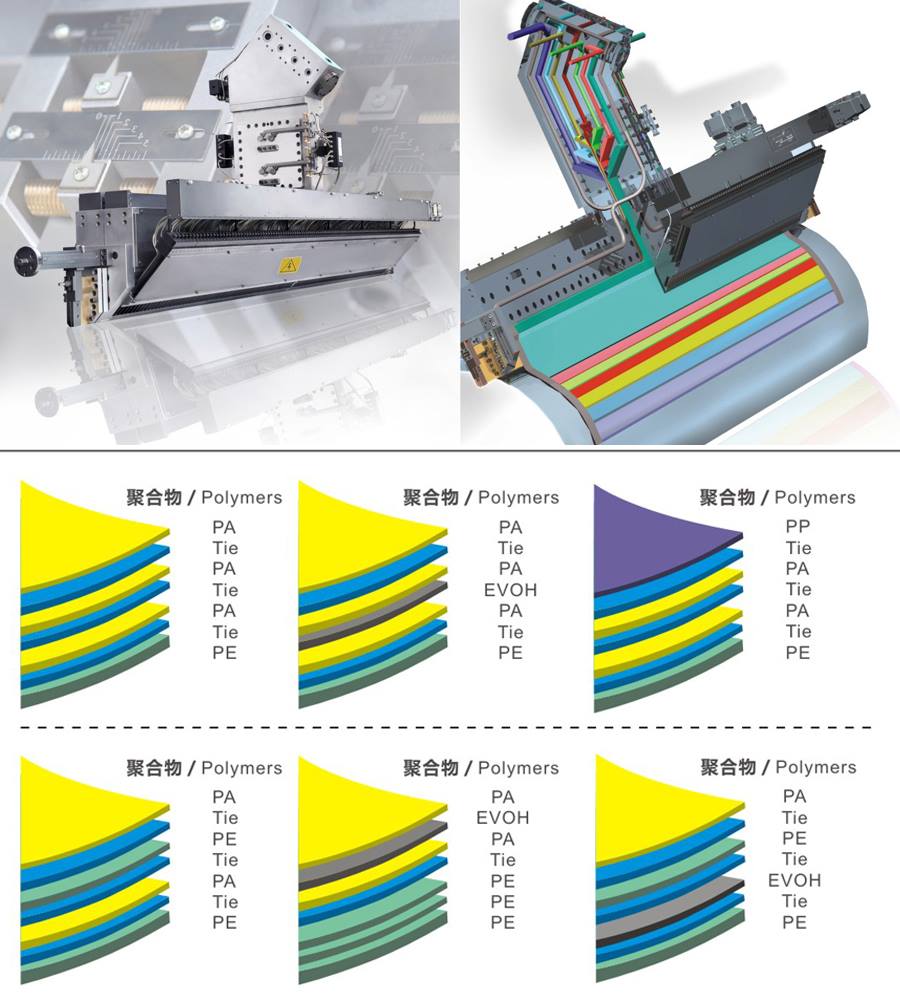

· Internal or external deckle can be equipped selectively.

· The unique edge sealing structure and edge covering design helps to save raw material thus save the cost.

Traditional die width For CPP/CPE film:2000mm,2500mm,3000mm,3500mm,3600mm,4500mm,5000mm,5500mm,6000mm or customized.

Other Products

Other Products