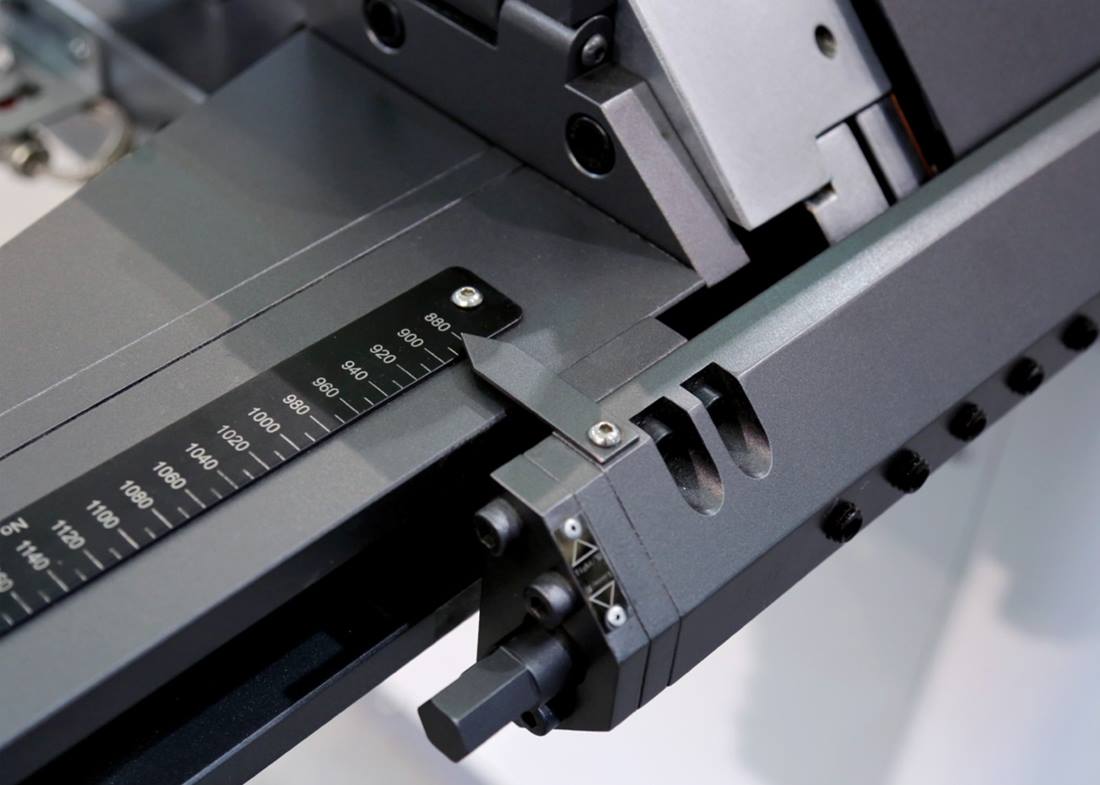

Fast lip open system will shorten the thickness adjustment time apparently, compared to ordinary adjustment time which is around 20 minutes, the fast lip open system can finish the adjustment within 2 minutes without halting the line.

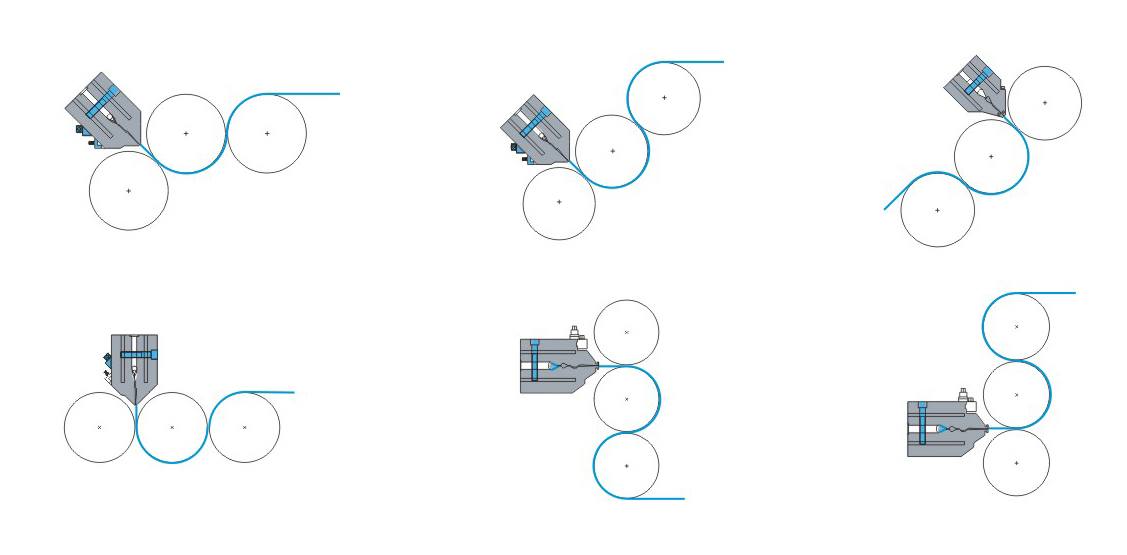

· Better roller approximation with internal deckle,more easily to be disassembled. Can be adjusted on line and works at high temperature.

· Dedicated sharp design for die lip,shortens the distance from die lip and shaping roller and gets high-quality product.

· Adopting high-quality alloy

steel,coat-hanger flow channel and unique design of restrictor-bar

without dead corner, effectively overcome the corrosivity of PVC. It

can be co-extruded through feed block to get perfect composite foamed

board.

· Special design for the flow channel and die lip, suitable for different types of foamed materials.

· Die lip temperature control unit, ensures to get foamed board with different foam rates.

· Can produce co-extruded foamed board,with rigid surface layer and foamed inner layer.

Through special flow channel design and multi-layer co-extrusion feed block, can get multi-layer product with combination of different widths and colors.

Different die structures will be designed for different ways of installation.

Specification:max width at 8000mm, thickness can reach 50-60mm. Can be customized.

Other Products

Other Products